| Extrusion coating / coating extrusion coating, extrusion laminating medium | |

| datetime:2015-03-30 Hits:2661 | |

In the extrusion coating process and the composite, after formation of the high temperature melted resin film, and then coated onto a flat substrate moving, these substrates include paper, cardboard, metal foil or plastic film. Then, the substrate is coated to go through a series of counter-rotating rollers, the substrate and coating in full contact, resulting in adhesion.Extrusion coating process technology Applications include: 1 car A full set of interior parts, such as interior roof, door lining and interior lining, underlay and so on. Base material is hemp, wood, non-woven. Coextrusion coating material is PP, PE, ABS and is filled PP. Basically, the above structure can be in the case of high output capacity to be produced in one operation.

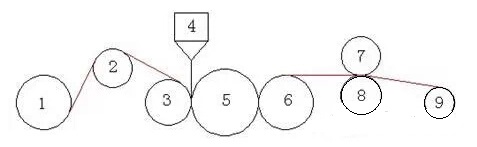

Such as oxygen and light barrier properties of fresh milk packaging offer septum. Material: paper, cardboard Coating material: PE1 and PE2. Each having special properties, such as heat sealing, every light or oxygen barrier. Currently, extrusion laminating technology is only used in the production of composite films. After the extruded composite is a thermoplastic resin, after the plastic extruder melt plastics by T-die extrusion coated on a substrate, while the other substrate composite sticking together, made of composite cooling the method of film. Extrusion coating is continuous and uniform thermoplastic resin extruded directly on a substrate cooling rolling into a composite film, not with another substrate bonding process. In practice, often the extrusion coating / coating classified as extrusion lamination. Extrusion lamination Currently there are three ways: single extrusion lamination, tandem extrusion lamination, coextrusion composite. Extrusion laminating process equipment diagram below.  1- unwinding; 2- guide roller tension control; 3 - a silicone rubber roller; 4- extruder; 5- steel roller; 6- cooling roll; 7,8-off roller; 9- rolling Advantages of extrusion lamination are as follows:

|

|

| Prev: PLC Systems Selection Method | |

| Next: Common plastic material processing temperature, specific gravity and shrinkage table | Back>> |

All rights reserved:Suzhou GWELL machinery co., LTD The phone:15906228589 13906225966

The interpretation Suzhou GWELL machinery co., LTD company ICP for su 10218247

The law of the People's Republic of China telecom and information services

business license do not establish a mirror