Global PV industry opened a new round of economic cycle, rapid heating China, Japan and the US PV market this round of economic cycle, continuous improvement of photovoltaic technology to promote PV market segmentation level rising, except the ground station, distribution application Type style and other traditional PV, the combined application of PV technology and civil products began to show life. In this paper, EVA and PVB PV modules to the two materials characteristics comparative analysis of its technical characteristics.

EVA film solar cell packaging field advantage significantly

Packaging adhesive material used in crystalline silicon solar cell industry as adhesive. Before the 1980s, at home and abroad have tried to use a liquid silicone resin and polyvinyl butyral resin sheet (PVB), but the price is high, harsh construction conditions, was not good and was eliminated.

Since the 1980s started to develop overseas EVA film, it is a hot melt adhesive film, non-tacky at room temperature and with blocking resistance will occur after certain conditions, hot melt adhesive and crosslinking. Which were quite satisfied with the results obtained in the solar cell encapsulation and outdoor use.

EVA (Ethylene Vinyl Acetate: ethylene - vinyl acetate copolymer)

EVA is a hot melt adhesive, i.e., at room temperature, EVA is solid, not sticky, translucent poor. When heated to a certain temperature the EVA, EVA melt adhesive on an object in contact with it. EVA for solar cell package is designed thermosetting hot melt adhesive, which is heated and melted at the same time cross-linking reaction occurs.

When the temperature is low, the crosslinking reaction rate is very slow, the completion time required to cure a long, whereas the time required is relatively short. So to choose a suitable lamination temperature, the EVA access to liquidity in the melt while curing reaction. As the reaction proceeds, the degree of crosslinking increases, EVA loss of mobility, play a role in the package.

At a temperature as follows:

Melting temperature (70-80 ℃). In this case heat to melt EVA, mobility, and is the best time to vacuum.

The curing temperature. EVA crosslinking agent contained at this generation of free radicals, molecules between EVA crosslinking, produce three-dimensional network structure, fluidity, high viscosity. The temperature suitable for laminated components, its structure more closely with the glass, the higher caking backplane.

Greater than the curing temperature. In this case the crosslinking agent decomposition gas, easy to assembly bubbles, while EVA crosslinking decreased, easy to cure yellow, contraction.

PVB (Poly vinyl butyral: polyvinyl butyral)

In 1935, US scientists have invented a way to use the sandwich is sandwiched between two layers of ordinary glass, polymer materials - polyvinyl butyral, the English name for POLYVINLBUTARAL, abbreviated as PVB.

It is a condensation reaction of a polymer formed by a polymer and polyvinyl butyral, nearly 23 per cent by weight of vinyl alcohol in the final polymer. Such polyvinyl butyral plus a special plasticizer (usually triethylene glycol ester) plasticized, through an extruder and precise thickness control system formed of a continuous 0.38 ~ 1. 52mm thick film.

Difference between the two

1. Applications

EVA is mainly used for crystalline silicon cell packaging, there is also a small part of the film, mainly protect the battery and the battery cover glass plate and close fitting role. The products currently on the market use Dupont's Tedlar most famous, but there are many other international companies in the production of various products, such as 3M, etc., are also a few domestic producers can be used in solar energy, such as Foster, Swift g, preferably sea Granville;

PVB is mainly used in the thin-film battery, double glazing assembly building integrated (BIPV) and other fields, the production company and product models are less, currently Dupont, Kuraray, etc, are also a few companies are trying to produce, such as Xin Fu medicine and so on.

2, the lamination process.

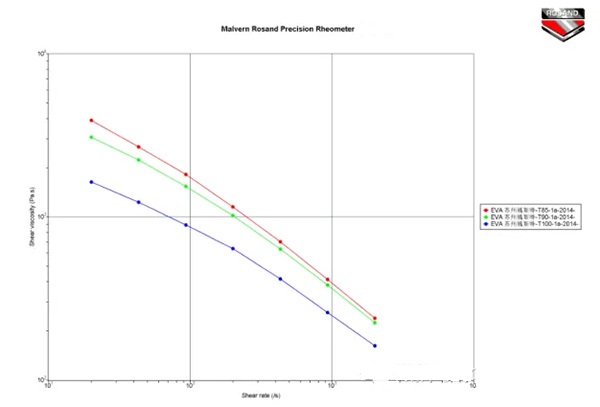

PVB, EVA is not the same temperature requirements. EVA thermoplastic good, the equipment requires no PVB high. PVB high temperature requirements (about 155 ℃), for laminating machine is relatively high.

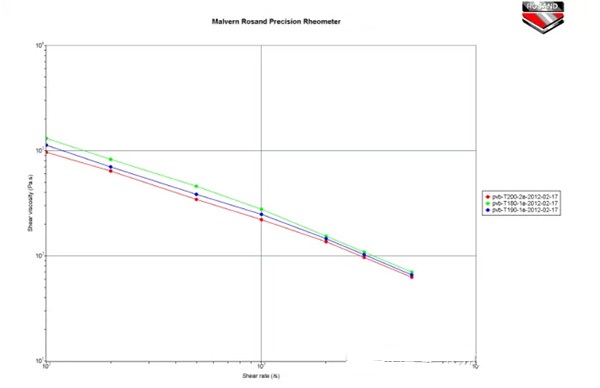

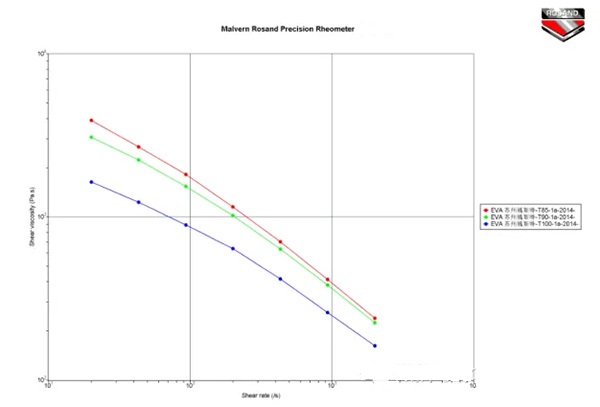

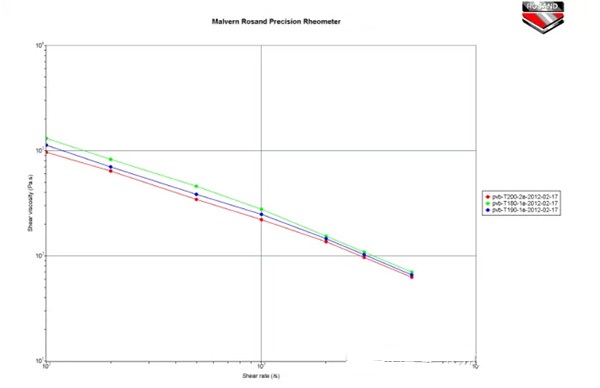

Legend: PVB EVA material shear rate - comparative shear viscosity curves

3, other

PVB is building materials, gas barrier performance is very good, and very good adhesive properties, much better weather resistance. The disadvantage is that poor water vapor barrier properties, which solar cells are unacceptable. And too soft and difficult to operate. EVA's price is more than three times.

Full support for your product development

They are hot-melt EVA and PVB film, are mature products, each with its advantages and disadvantages, application in different areas. Trend encapsulated crystalline silicon solar modules is the use of EVA, its performance is excellent, affordable, favored by many module manufacturers products; PVB is very suitable for the double glass components and thin-film battery components and building integration and other fields, in these areas status PVB is irreplaceable.

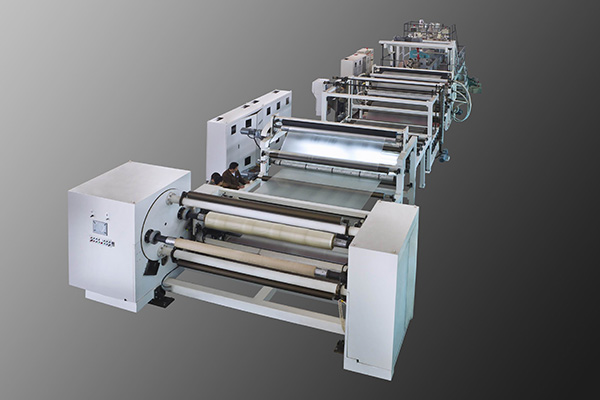

According to the characteristics of different materials, we have been the source of innovation, product design, through the absorption of foreign advanced technology, the characteristics of the raw materials for plastics analysis of reading, to design the most in line with the actual needs of PVB and EVA film production line. Especially for the development of new materials, to provide customized solutions to help customers achieve product upgrading and transformation of the minimum flow.

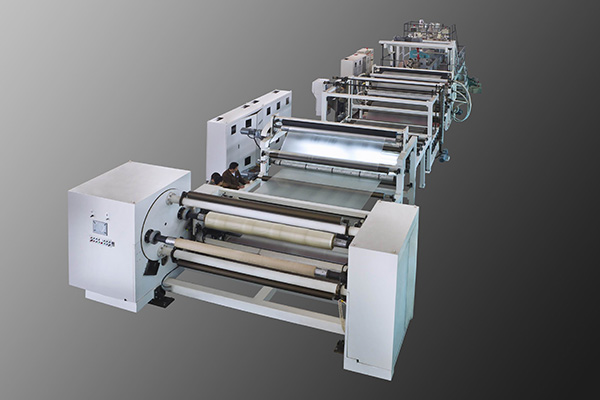

Suzhou Jin Weier Machinery Co., Ltd. EVA film production line and PVB film production line equipment for its fast, stable and efficient automated system device, a unique design and processing technology, precision products to control the film thickness, thermal shrinkage and protect silicon wafers and components durability, photoelectric conversion efficiency.

2300mm EVA film solar production line 4000mm PVB film production line